We offer full project management by providing solutions and plans specific to asset life expectancy by being cost effective. We support clients to identify medium to long term integrity requirements and define an optimum methodology that is unique to suit their specific asset requirements by combining a wide range of tools:

Surface Preparation

Surface Preparation to industry standard using the following methods:

- Mechanical Preparation/ Power Tooling

- Wet Abrasive Blasting

- Dry Abrasive Blasting using grit and garnett

- Vacuum Blasting

- Ultra-High Pressure Blasting

Anticorrosion Coating

Our main coatings services include:

- Technical support and advice

- Site surveys

- Providing NACE accredited inspectors

- Fabric Maintenance Campaigns

Typical coating applications include:

- Internal vessel and tank linings

- External corrosion protection

- Helidecks and non-skid walkways

- Fusion bonded epoxy

- Thermal sprayed aluminum

- Pipe and valve internal lining replacement

- Specialist coating systems

- Corrosion Under Insulation Remediation

Climate controlled warehouse

Thermoplastic Coating

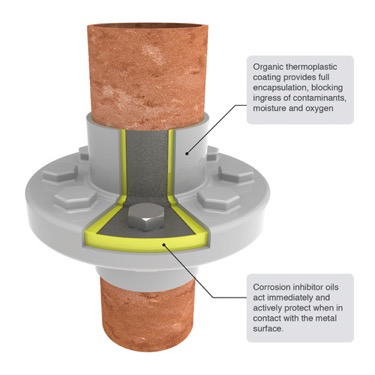

Exclusive applicator and supplier of OXIFREE in CDI and Ghana

Oxifree Metal Protection has been established to tackle the global cost of corrosion which affects all sectors of industry.

Our solution is:

- Oxifree TM198, a thermoplastic coating for the protection of metallic components.Oxifree TM198 is melted down from a solid resin and applied using a heated hose and gun to provide 100% protection against corrosion and contamination.

- Oxitape, is a moisture activated composite tape that cures in air or water to form a hard shell

Oxifree TM198

TM198 is melted down from a solid resin and applied using a heated hose and gun. It provides a pliable thermoplastic barrier coating, which will protect all types of metal components against galvanic pitting and atmospheric corrosion as well as protecting from water and dust ingress. It is ideal for flanges and valves on process piping, and long term storage of equipment in normal atmospheric conditions. The material can easily be cut and removed for access and maintenance, the area of removed material can then be refilled as the newly applied material will bond to the existing TM198. Alternatively the protected substrate can be inspected via UT directly through the material. There is no downtime during application and protection is provided immediately, bringing savings to both CapEx and OpEx. TM198 is proven to extend the lifecyle of components and reduce maintenance costs.

The core application machines have undergone extensive development and testing and come in 2 different sizes: 12lbs/5.5kg and 50lbs/22kg to cater for a total range of application criteria. The larger machine is available IECEx certified.

Testing:

Oxifree material has been thoroughly tested to 11,688 hours of "industry standard" Salt Spray test, which complies with ASTM B117 corrosion testing which is equivalent to in excess of 50 years ‘in the field'. Oxifree has also been through ASTM G56 UV/Weathering test and again exceeded required longevity with ease. :

- ASTM B117 – Salt spray test – successfully tested to 4x industry benchmark

- ASTM G154 UV - Weathering test successfully exceeded standards

- GOL492/09 Volatile Organic Compound Test (<0.05%)

- Boeing BSS 7239 – Successful smoke toxicity test

- ASTM E662 – Successful smoke generation test

- ASTM G85-94 – Annex A5 prohesion test – successfully approved with 1000hrs testing

- BS EN 13823 – Single burning item test – Complete and passed within standards

- ASTM D790 - Cryogenic bend flexibility

- ASTM D149 – Dielectric strength testing

- BS2782 Pt.2 - Volumetric resistivity testing (Electrical resistance)

- ASTM D7359 – 13 Standard Test Method for Total Fluorine, Chlorine and Sulfur in Aromatic Hydrocarbons

- ASTM E968 - Sand abrasion resistance

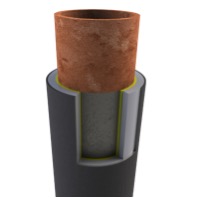

Oxitape

- Oxitape is a moisture activated composite tape that cures in air or water to form a hard shell

- It is a protective shell that is both chemical, UV, abrasion and impact resistant

- Suitable for application over TM198 in areas subject to heavy environmental impact both above and below ground, e.g. wave slam, impact from debris and for equipment to be buried underground. Especially suitable for the splash zone in the coastal/offshore environment.

- Oxitape is simply applied over the top of Oxifree TM198 providing a defensive shell that offers complete protection from contact as well as corrosion and contamination

- Following the application of TM198, Oxitape can be applied immediately.Typical application time for a flange on a 2 inch pipe is 5 minutes

- Both products can be easily removed making it easy to conduct inspection and maintenance

- The combination of Oxifree TM198 and Oxitape can be applied very quickly to provide long term protection

- The combination of both Oxifree TM198 and Oxitape brings the benefits of TM198 to an even wider range of applications, assets and environments

- Oxitape can withstand impact force of over 300ft/lbs without penetration

- Oxitape has a high abrasion resistance, abrasion penetration of 0.076mm per second achieved with #80 Aluminium Oxide Blast media applied at 80 Psi, applied from blast nozzle 25mm from test sample.

- Oxitape brings the benefits of TM198 to a wider range of applications assets and environments including: splash zone, ground-air pipe interface, pipe support, buried pipe

- Savings to both operational and capital expenditure

- Protective shell for TM198, maintaining contact with substrate

- Resistant to chemicals, UV, abrasion and impact

- Easy and fast to apply with no process downtime

- Ready to use out of the packet, no preparation required

- Tailored solution - different roll lengths and sizes available

- Easily removed along with TM198 for maintenance and inspection and can be reapplied/wrapped

- Long term asset protection in harsh environments when combined with TM198

Pipe Wrapping

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Minima eaque ipsum, incidunt quam consectetur hic recusandae illum accusamus, aspernatur ipsam quisquam molestiae nostrum culpa temporibus natus sequi alias dolore deleniti.

Passive Fire Proofing Systems (Approved applicator of JOTACHAR)

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Minima eaque ipsum, incidunt quam consectetur hic recusandae illum accusamus, aspernatur ipsam quisquam molestiae nostrum culpa temporibus natus sequi alias dolore deleniti.

Insulation

Our insulation capabilities cover:

-

Hot and cold service applications

-

Fire protection

-

Metallic and Non-metallic cladding

-

Corrosion-Under-Insulation inspection and control

Piping and PSV Testing

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Minima eaque ipsum, incidunt quam consectetur hic recusandae illum accusamus, aspernatur ipsam quisquam molestiae nostrum culpa temporibus natus sequi alias dolore deleniti.

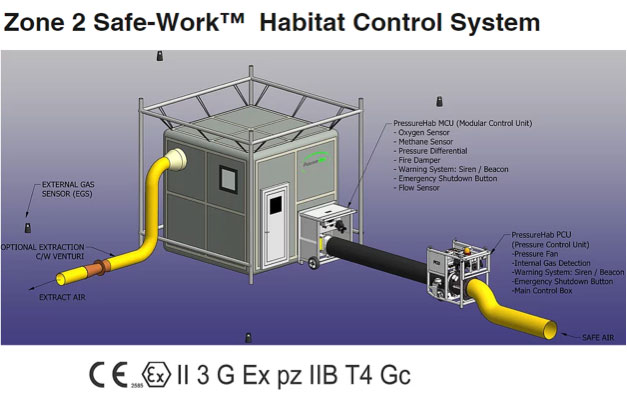

Modular Welding Habitats and Safe Stop Control System (exclusive supplier of pressurehab in CDI)

PressureHab is a solution providing market-leading certified pressurized hot work habitat.

Pressurized hot work habitat systems provide partners & customers with an economical product, engineered to protect people and facilities in hazardous environments where flammable or toxic gases, or other substances, may be present.

This system allows hot work and maintenance to continue without the expense of shutting down parts of a facility, PressureHab’s hot work habitats are used to provide safety and cost savings in a diverse range of industries and locations such as on oil rigs & marine operations, and at refineries, chemical processing plants, distilleries, food manufacturing and processing factories, utility and water treatment sites.

These pressurized Hot Work Habitat Systems are compact & lightweight, and their innovation and certification surpass all other habitat systems on the market.